What is the single most important safety feature of any electrical device? The answer is its insulation. A flaw in this protective barrier can lead to a complete breakdown of a device or even worse, an electrical shock. To ensure that a product’s insulation is truly safe, manufacturers perform a rigorous check known as a High-Potential (Hipot) test. This critical test verifies that the protective barrier can withstand extreme electrical stress without breaking down.

While there are many ways to perform this test, the most common is with alternating current. AC Hipot testing deliberately overstresses a component’s insulation by applying a high AC voltage between conductors and ground. This process reveals manufacturing defects and potential weak spots that might not be visible to the naked eye, such as pinholes, tiny cracks, or inadequate spacing. Because of its effectiveness, regulatory bodies like UL (Underwriters Laboratories) and the IEC (International Electrotechnical Commission) require AC Hipot testing as a mandatory step in quality control for countless products before they ever reach the end user. This ensures every piece of equipment, from consumer electronics to medical devices, is safe and reliable.

What Is AC Hipot Testing?

AC Hipot testing—also known as AC withstand voltage or dielectric withstand testing—applies a high alternating voltage, typically at standard power frequencies of 50 or 60 Hz, to a device. This process tests the strength of the insulation system to ensure it can reliably withstand specified voltage levels without an electrical breakdown or excessive leakage current.

Imagine the insulation as a strong barrier between two electrical conductors. When the high voltage is applied, a tiny leakage current might try to pass through, but the barrier should hold. If this current remains below a preset threshold for a specific duration, the device passes. If it exceeds that threshold or if a breakdown occurs, it fails. (Source: Wevolver)

AC vs. DC Hipot Testing: The Key Difference

While both AC and DC Hipot tests serve the same purpose of verifying insulation integrity, they achieve it in fundamentally different ways.

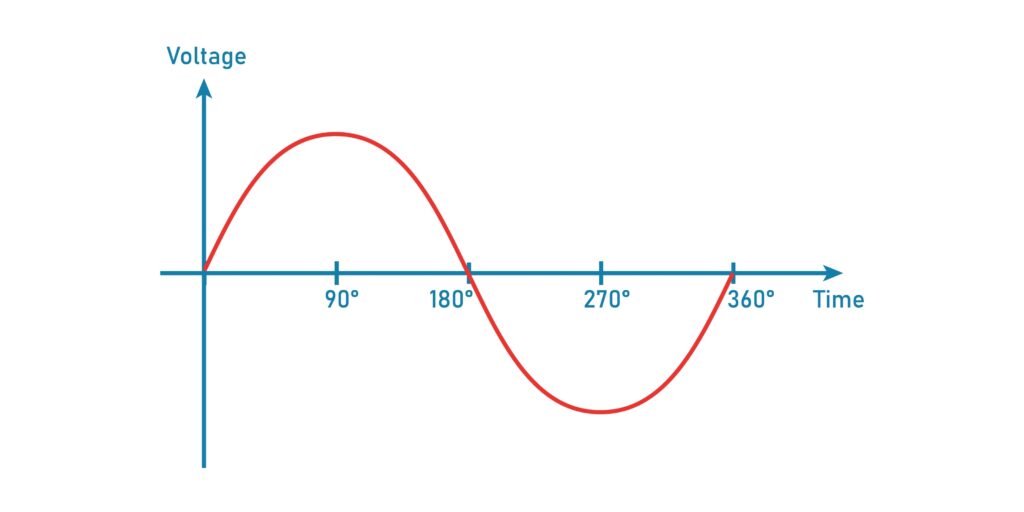

The AC test applies a bidirectional, alternating voltage that simulates real-world operating conditions, which is ideal for testing the integrity of a component’s insulation against the dynamic stress of the power grid.

A DC test, on the other hand, applies a one-directional voltage.

While DC testing can be more sensitive to certain types of flaws and requires smaller, lighter equipment, it doesn’t replicate the symmetrical stress an AC-powered device will face in the field. This key distinction is why AC testing remains the gold standard for most consumer and industrial products

Key Characteristics and Standards

AC Hipot tests are a cornerstone of electrical safety, and their characteristics are defined by global standards. The test applies a voltage that is typically calculated as 2 × rated voltage plus 1000V. This specific formula ensures that the device can handle not only its normal operating voltage but also potential voltage spikes from the power grid.

The primary goal of the test is to detect manufacturing defects, insulation weaknesses, and issues with clearances or creepage distances. Because of its effectiveness, AC Hipot testing is a mandatory requirement from most international safety standards and organizations, including UL, IEC, CSA (Canadian Standards Association), and EN (European Norm). (Source: EEP – Electrical Engineering Portal)

Why Use AC Hipot Testing?

AC Hipot testing is often the preferred choice because it closely mimics real-world operating conditions and applies a more realistic, symmetrical stress across insulation. Most equipment operates on AC power, and testing with an alternating current ensures the insulation performs under conditions it will actually face in the field.

A key advantage is that the alternating polarity ensures a uniform stress distribution that helps detect both surface and volumetric defects (Source: Vitrek).

Unlike DC, which stresses the insulation in only one direction, AC testing cycles between positive and negative, catching defects that a single-polarity test might miss. This also means you don’t need to discharge the device after testing, as the AC signal naturally returns to a zero-crossing point, making the process faster and safer.

Understanding Test Parameters

To conduct an AC Hipot test correctly, you need to understand three key parameters: the test voltage, the current trip limit, and the duration. Think of these as the test’s strength, tolerance, and endurance.

1. Test Voltage Selection

The test voltage is the most important parameter and determines how much electrical stress the insulation will endure. It’s not just a random number; it’s a specific value defined by international safety standards. A common formula for setting this voltage is 2 × the rated voltage + 1000V (Source: EEP – Electrical Engineering Portal). The “1000V” accounts for potential voltage spikes that a device might encounter from the power grid, while the “2 × rated voltage” serves as a safety factor.

For example, a standard consumer product rated at 120VAC would be tested at approximately 1240V. Heavier-duty industrial equipment, however, often requires a higher minimum test voltage—sometimes up to 1500V or more—to reflect its more demanding operating environment.

2. Current Trip Limits

The current trip limit defines the maximum amount of leakage current the insulation can tolerate before the test automatically fails. A tiny amount of current will always pass through insulation, but if this current exceeds the preset limit, it indicates a breakdown or a significant flaw.

The limit is a crucial safety parameter that varies widely based on the size and purpose of the device:

- Small electronics: typically a very low threshold (0.5–2 mA).

- Home appliances: a slightly higher tolerance (2–10 mA).

- Heavy industrial equipment: a much higher limit (10–100 mA or more), given the larger size of the components.

These limits are set to align with industry safety standards but should always be customized based on the specific device being tested.

3. Duration

The final parameter is the duration of the test. A typical routine test for production lines is usually 60 seconds, which is often required by standards like UL and IEC. For design validation or type testing, the duration may extend to several minutes. While a longer duration builds greater confidence in the insulation’s long-term reliability, it also increases the total test time and can put more stress on the equipment.

AC Hipot Tester Features

Modern AC Hipot testers are far more than simple voltage sources; they are sophisticated systems designed for precision, safety, and efficiency.

At their core, these testers come with essential features like a variable voltage output that allows for fine-tuned control over the test. You can also set adjustable current trip limits to protect both the device and the operator. For streamlined operation and safety, they include automatic test sequencing, safety interlocks, and emergency stops. The results are clearly displayed through pass/fail indicators, and integrated data logging provides essential documentation for quality control and regulatory compliance.

Beyond the basics, advanced AC Hipot testers offer features that are crucial for modern manufacturing. Multi-channel testing allows you to test several devices at once, significantly boosting throughput. Programmable sequences enable full automation, while remote control and monitoring make it easy to integrate the tester into a production line. Some systems even include statistical analysis to provide valuable quality control insights. These capabilities ensure consistency, improve productivity, and enhance safety across large-scale manufacturing environments.

Safety Considerations and Precautions

AC Hipot testing involves high voltages that pose serious hazards, so reducing these risks starts with robust safety practices and equipment design.

To ensure operator safety, comprehensive high-voltage training is essential. Personnel must understand and regularly drill on emergency shutdown protocols and be equipped with proper PPE (Personal Protective Equipment), such as insulated gloves and mats. Regular safety audits and procedural updates are also important to ensure all practices remain current and effective.

Beyond the operator, the testing equipment itself must have built-in safeguards. Key equipment safety features include ground fault interrupters and easily accessible emergency-stop switches to cut power instantly in an emergency. Interlocked fixtures prevent accidental contact with high-voltage points, while both visual and audible alarms provide clear warnings when a test is active. Finally, automatic discharge circuits are critical for safely eliminating any stored charge after the test is complete.

These combined measures not only protect personnel but also improve the overall reliability of the testing process.

Test Procedures and Methods

Hipot testing can be performed using either a manual or an automated approach, each with its own set of procedures and benefits.

A manual test procedure is a hands-on method often used for low-volume or unique testing scenarios. It involves several key steps: first, an operator must confirm the proper setup and connections, then manually configure the test voltage and current thresholds. The test is then initiated, and the operator observes the current levels and records a pass or fail outcome. After the test is complete, the device must be safely discharged before it can be handled. Due to the inherent risk and time-consuming nature of these steps, manual testing is not ideal for large-scale production.

This is where automated testing comes in. Automated systems are the standard for modern, high-volume manufacturing environments. They offer unparalleled consistency, speed, and operator safety by executing complex sequences unattended. An automated tester can rapidly run tests on multiple channels at once, automatically log all data, and integrate seamlessly with manufacturing systems (MES) or enterprise resource planning (ERP) systems. This shift from a hands-on procedure to a smooth, automated process makes high-volume testing far more efficient, reliable, and safe.

Applications Across Industries

AC Hipot testing is a cornerstone of electrical safety, finding use across a wide range of industries where product integrity is paramount.

In the medical device sector, patient safety is the ultimate priority. This equipment must comply with standards like IEC 60601-1, which mandates strict insulation testing to eliminate any risk of electric shock.

For consumer electronics, Hipot tests are essential to meet UL and IEC safety requirements, preventing insulation breakdowns or electrical shocks in home environments, which can cause devastating fires.

Finally, in industrial equipment, heavy-duty machinery is often exposed to harsh conditions, such as extreme temperatures, moisture, or vibration, which can degrade insulation over time. Regular Hipot testing ensures continued safe operation and protects workers in these demanding environments.

Common Test Failures & Troubleshooting

A test failure isn’t just a hurdle; it’s a critical signal that an electrical component has a hidden flaw. Understanding the common failure modes is the first step toward effective troubleshooting and preventing future issues.

A Hipot test can fail due to manufacturing defects like pinholes, nicks, or delamination in the insulation. It can also be caused by contamination from conductive debris or moisture, or simply from inadequate creepage and clearance distances between components. Environmental factors like vibration or extreme heat can also degrade the insulation over time, leading to a failure.

When a failure occurs, the corrective actions are direct and targeted. First, audit your QA processes to catch manufacturing defects earlier. If contamination is the source, you need to clean or replace contaminated parts. For design-related issues, you may need to redesign for better air gaps and more generous creepage margins. Finally, implementing preventive maintenance protocols can help reduce environmental degradation. By addressing these root causes, you not only fix the immediate problem but also improve the overall quality and reliability of your products.

Equipment Selection Criteria

When choosing an AC Hipot tester, you should evaluate equipment based on three key areas: performance requirements, production environment, and regulatory compliance.

For performance requirements, consider the maximum voltage output and the resolution of the current measurement. You also need to look at controls for ramping and timing accuracy, as these are crucial for a reliable test. Modern testers should also come with data logging capabilities to ensure traceability for quality control.

The production environment is another vital factor. If you need high efficiency, look for testers with batch or multi-channel capabilities. If your production line is automated, you’ll want a tester that can integrate with your control systems. This also ties into operator expertise—the right equipment can simplify the process, even for less experienced personnel.

Finally, regulatory requirements are very important. Ensure the equipment conforms to the latest international standards, such as IEC 62368-1, which is an important safety standard for audio/video, information, and communication technology (Source: Vitrek). Choosing a tester with future-proof features and robust calibration traceability can also save you significant costs down the line.

Industry Standards & Regulations

Compliance with safety regulations is the final, significant step in the AC Hipot testing process. The test aligns with numerous global safety standards, including IEC 62368-1 (which has replaced IEC 60950-1 for IT and audio/video equipment), IEC 60601 for medical devices, and IEC 60335 for household appliances. You’ll also find regional variants from organizations like UL, CSA, and EN. To ensure compliance and product safety, manufacturers must always reference the latest version of the relevant standard in their region.

Future Trends in AC Hipot Testing

The future of AC Hipot testing is being shaped by three major trends: enhanced automation, improved diagnostics, and advanced connectivity. These changes are making the testing process smarter, faster, and more integrated than ever before.

Enhanced automation means a deeper, more seamless integration with manufacturing systems. Testers will be able to adapt to different products automatically and provide real-time analytics without human intervention, ensuring greater consistency and efficiency.

Improved diagnostics will give operators more information than a simple pass or fail result. Future testers will be able to pinpoint the exact type of failure, such as partial discharge—small electrical sparks within the insulation—or surface tracking, which is the formation of a carbonized path on the insulation’s surface. This advanced insight will enable targeted corrective actions, saving time and resources.

Finally, connectivity and data management will transform how tests are monitored. Cloud-enabled testers will allow for centralized data dashboards, enabling predictive maintenance and remote access for quality control teams. This means managers will be able to monitor the testing process from anywhere in the world, ensuring proactive quality control.

Conclusion

AC Hipot testing is a foundational and indispensable method for ensuring the safety and reliability of electrical equipment. When executed correctly, it can detect hidden defects before they have a chance to become a hazard. By focusing on modern test parameters, high-quality equipment, and robust safety protocols, organizations can efficiently scale their testing program without ever compromising on quality. Ultimately, a strict Hipot testing program is more than a compliance step—it’s a strategic investment in product integrity and brand reputation.

Ready to Enhance Your Electrical Safety?

The path to a safer, more reliable product begins with your testing program. Take the first step by evaluating your current setup and considering an upgrade to modern, automated AC Hipot testers. Equip your team with the right training, integrate standards-based testing into your workflow, and leverage automated data logging for complete traceability and continuous quality improvement.

To get started, explore standardized testing services or contact a trusted supplier today to find the right equipment for your needs.

Frequently Asked Questions (FAQ)

Q1: Why is AC Hipot testing preferred for AC-powered devices?

A: AC Hipot testing is preferred because it mimics actual operating conditions. By applying an alternating voltage, it tests the insulation under both positive and negative polarity, which is a more realistic test of its integrity than a single-polarity DC test. This approach is required by most safety standards.

Q2: How is the test voltage determined?

A: The test voltage is not a random number. It’s a specific value set by international standards. A common formula is Test Voltage = 2 × Rated Voltage + 1000V. This formula ensures the device can withstand both its normal operating voltage and potential voltage spikes from the power grid.

Q3: What makes a Hipot test fail?

A: A device fails if the leakage current through the insulation exceeds the set trip limit during the test. Failure can also be caused by an electrical breakdown or a flashover, which is an uncontrolled electrical discharge around or over the insulation itself. These indicate a significant defect or weakness in the insulation.

Q4: What safety precautions are critical?

A: Given the high-voltage risks, critical safety measures include an extensive operator training, the use of Personal Protective Equipment (PPE), and robust equipment safety features like interlocks, emergency-stop switches, and automatic discharge circuits to eliminate any stored charge after the test.

Q5: How do I choose the right AC Hipot tester?

A: To choose the right tester, evaluate its performance (max voltage, current resolution), production needs (automation, data logging), and regulatory compliance. Choosing a tester that meets future standards is key to a cost-effective investment.