Introduction: The Backbone of Modern Electrification

In 2025, DC power supplies are doing much more than just providing power. They are evolving into highly flexible, intelligent systems designed to keep pace with a world moving toward total electrification.

Specifically, high-capacity, wide-range DC power supplies have become the indispensable backbone of today’s most critical sectors. Whether it’s testing the massive battery arrays in electric vehicles (EVs), driving high-speed industrial automation, or managing the relentless power demands of AI data centers, these systems are being asked to do more in less space.

As the global push for energy efficiency intensifies, these advanced supplies are delivering a level of performance and “smart” integration that was once considered impossible.

What Are High-Capacity, Wide-Range DC Power Supplies?

To understand these systems, think of a traditional power supply like a car with only one gear: it can go fast (high voltage) or it can pull a heavy load (high current), but it can’t do both efficiently. Modern Wide-Range (or Auto-Ranging) power supplies are like having a sophisticated automatic transmission.

At their core, these units convert electrical energy into a stable direct current (DC) output. However, they differ from standard supplies in two major ways:

- High-Capacity Performance: These systems are built for “heavy lifting“. They deliver massive power levels, ranging from tens of kilowatts (kW) to several megawatts (MW). This is the kind of power required to test an entire electric vehicle drivetrain or run a massive industrial plating line.

- The “Auto-Ranging” Advantage: Unlike traditional supplies that have a fixed maximum voltage and current, wide-range units can automatically adjust their output. They can provide high voltage at lower currents, or high current at lower voltages, all while maintaining their maximum power rating.

Why This Matters in the Real World

For engineers and technicians, this flexibility is a total game-changer. In a testing lab, you might need to test a 400V battery in the morning and a high-current 12V motor in the afternoon.

In the past, you would have needed two separate, expensive power supplies. Today, a single Wide-Range unit can handle both tasks. This doesn’t just save money, it also saves valuable rack space and simplifies the entire testing environment.

Market Growth: A Broader Landscape of Demand

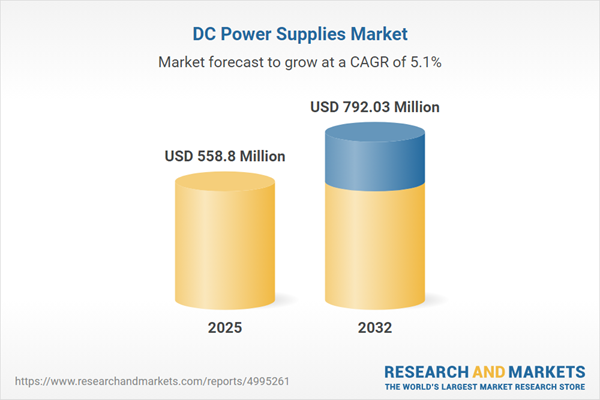

The demand for advanced DC power isn’t just growing, it’s accelerating! As we move through 2025, the global market is shifting from basic power delivery to high-performance, programmable infrastructure.

Why the Surge?

According to industry analysis, the DC power supply market is on a strong upward trajectory, projected to grow from roughly USD 559 million in 2025 to over USD 792 million by 2032.

This growth is being pulled by a few massive global shifts:

- The EV Explosion: It’s not just about the cars. The entire supply chain, from battery manufacturing to ultra-fast charging stations, requires massive amounts of high-capacity DC power for testing and operation.

- The “AI Factory” Era: Data centers are no longer just storage units, they are “AI factories“. To power high-density racks and the specialized GPUs that run AI, facilities are moving toward higher DC voltage architectures (like 48V and even 800V) to minimize energy loss.

- Industrial Autonomy: As factories embrace Industry 4.0, robotics and automated guided vehicles (AGVs) are becoming standard. These systems require precise, robust DC power that can communicate with a central network in real-time.

The New “Standard”

In fields like telecommunications and automotive electronics, the “dumb” power supply is being phased out. Today’s industry standard is a unit with a wide operating range and a programmable interface. This allows a single piece of equipment to adapt to different tasks, making the entire infrastructure more reliable and much easier to scale.

Trend 1: Wide-Bandgap Semiconductors — GaN and SiC Take Center Stage

The most significant leap in DC power supply design comes from the shift away from traditional silicon toward Wide-Bandgap (WBG) semiconductors, specifically Gallium Nitride (GaN) and Silicon Carbide (SiC).

While silicon has powered our world for decades, it is reaching its physical limits in terms of heat management and speed. WBG materials are the “super-materials” that allow 2025 systems to break through those limits.

Why GaN and SiC Are Game-Changers

These materials allow power supplies to operate at higher voltages, faster switching frequencies, and higher temperatures than ever before. This creates a ripple effect of benefits:

- Superior Efficiency: Wide-bandgap materials such as GaN and SiC offer notable efficiency advantages over traditional silicon components, enabling faster switching and lower energy loss. In high-power industrial settings, this translates into thousands of dollars in annual energy savings.

- Massive Miniaturization: By drastically reducing heat generation, these materials eliminate the need for bulky cooling hardware. This allows high-capacity performance to fit into a fraction of the space; in fact, recent breakthroughs in radiation-resistant SiC technology have shown that power-to-volume ratios can be improved by up to 5 times!

- Extreme Resilience: SiC, in particular, is incredibly rugged. It can withstand the harsh thermal and electrical environments found in EV powertrains and renewable energy inverters, making the power supply more reliable over its entire lifespan.

The Best of Both Worlds

In 2025, manufacturers are using these two materials strategically:

- GaN is the leader for high-frequency applications, making it perfect for compact 5G infrastructure and fast-charging systems.

- SiC is the “heavy lifter,” dominating high-voltage and high-current environments like electric vehicle drive systems and large-scale industrial converters.

Trend 2: Digital Control and Intelligent Monitoring

One of the most critical shifts in DC power design is the move from simple analog circuits to intelligent Digital Control Architectures.

What Does “Intelligent” Look Like?

Modern high-capacity units are now equipped with microcontrollers and digital signal processors (DSPs) that allow for:

- Remote Telemetry (automated collection and transmission of data and measurements) and Control: Engineers can now adjust voltage, current, and power limits from a central control room or even a mobile device. This is vital for large-scale operations like solar farms or massive data centers where physical access is difficult.

- Programmable Output Profiles: You can program the power supply to follow a specific curve, simulating a battery discharging over 24 hours or a sudden voltage spike in an EV motor. This flexibility allows one unit to perform the work of five different specialized supplies.

- Predictive Maintenance: This is the game-changer for Industry 4.0! Smart monitoring systems track internal health metrics like ripple voltage (residual periodic variation of the DC voltage which has been derived from an AC source) and thermal stress. If a component begins to degrade, the system alerts the operator before a failure occurs, preventing millions in potential lost production.

The Standard for R&D and Production

Because these systems offer such tight control and high precision, they have become the standard choice for high-value electronics testing.

In the EV sector, for example, the majority of testing systems now require programmable DC sources to simulate the complex power needs of modern battery management systems (BMS). By using digital controls, manufacturers like BYD and Tesla can accelerate their development cycles and ensure that every semiconductor and battery pack meets strict safety and reliability standards. (Source: Market Report Analytics)

Trend 3: Modular and Scalable Architectures — The “Pay-as-You-Grow” Advantage

In the past, purchasing a high-capacity power system was a high-risk gamble: you had to guess your power needs years in advance and buy a massive, expensive unit upfront. In 2025, that model has been replaced by modular and scalable architectures.

Flexibility by Design

Modular DC power supplies allow engineers to scale their output capacity by adding or removing individual power modules within a single rack, rather than replacing the entire unit. Think of it like a “Lego-style” approach to power:

- Fast Capacity Upgrades: If an EV test lab moves from testing 400V packs to 800V packs, they can simply plug in additional modules to meet the new requirement in minutes, not weeks.

- Reduced Initial Investment (CapEx): Companies can start with only the power they need today, reducing their upfront costs. They only pay for more capacity as their production or Research & Development (R&D) needs expand.

- Improved Serviceability: If a single module fails, the rest of the system can often keep running. Replacing a faulty module is a simple task that doesn’t require shutting down the entire facility.

Strategic Value in Rapidly Changing Industries

This scalability is particularly valuable in sectors where technology moves fast:

- EV Test Labs: As battery chemistries evolve, test systems must scale rapidly to keep up with higher power densities.

- Battery Energy Storage Systems (BESS): Modular systems allow grid operators to expand energy storage capacity incrementally as more renewable energy comes online.

- Large Industrial Drives: Smart factories can add power modules to their central DC bus as they add more robotic lines, ensuring they never have “trapped” or wasted power capacity.

The Bottom Line: Modular designs are becoming the “smart default” for 2025. By moving away from fixed-capacity units, organizations gain a level of agility that significantly lowers their total cost of ownership.

Trend 4: Advanced Thermal Management and Power Density

As DC power systems push into the megawatt range, heat dissipation has become the primary engineering challenge. In 2025, maintaining high performance is about how efficiently you can move heat away from those circuits.

The Shift to Liquid and Hybrid Cooling

Traditional air cooling is reaching its limits. For systems handling over 20kW to 30kW per rack, fans simply cannot move enough air to keep the components safe. Industry leaders are now adopting:

- Precision Liquid Cooling: Liquid and hybrid cooling methods ,compared to traditional fans, are becoming more common as engineers seek to manage heat more effectively in high-power systems, a crucial step given the density of modern designs.

- Direct-to-Chip (DTC) Solutions: Especially in AI data centers, coolant is sent directly to the power-hungry processors. This “hybrid” approach uses liquid for the hottest parts while maintaining standard air conditioning for the rest of the room.

- Intelligent Fan Arrays: For air-cooled units, “smart” fans now use AI algorithms to adjust speed based on real-time thermal telemetry, reducing noise and extending the fan’s lifespan.

Packing More Power into Less Space

The push for higher power density means packing more watts per cubic centimeter. This is essential for modern industrial cabinets and mobile power systems where space is a premium.

- 48V Busbar Architecture: Many data centers and factories are shifting from 12V to 48V DC distribution. This higher voltage allows for lower current, which means thinner wires, less resistive heat loss, and a much smaller physical footprint for the power distribution hardware.

- Miniaturized Magnetics: Advances in magnetic core materials and component design techniques are enabling transformers and inductors to become significantly more compact, helping modern high-capacity power supplies deliver more performance in smaller form factors.

The result: These thermal and density improvements don’t just save space, they directly impact the Total Cost of Ownership (TCO). Better cooling means fewer heat-related failures, which translates to a significantly longer lifespan for the equipment.

Key Applications: The Engines of DC Power Growth

High-capacity, wide-range DC power supplies are the critical infrastructure for the most advanced industries on the planet:

Automotive & EV Systems

The shift from 400V to 800V and even 1500V architectures in electric vehicles is the single biggest driver of this market. Modern testing facilities now require power platforms that can handle massive currents across these extreme voltage ranges.

- The Bidirectional Advantage: Testing an EV battery isn’t just about charging it. To simulate real-world driving (like regenerative braking), power supplies must be bidirectional, meaning they can both source and absorb (sink) power seamlessly.

- Efficiency at Scale: By using regenerative power supply technology, some advanced battery testing systems can recover a large portion of the energy discharged during tests and feed it back into the facility grid or local power system, reducing wasted energy and lowering overall electricity costs.

Industrial Automation & Robotics

In the “Smart Factory” era, precision is everything. High-capacity DC supplies provide the stable, ripple-free power needed for high-speed robotic arms and sensors.

- Variable Load Handling: Modern manufacturing lines are dynamic. As robots start and stop, they create massive, sudden changes in power demand. Wide-range DC supplies handle these fluctuations without sacrificing stability, ensuring 24/7 uptime.

Renewable Energy & Microgrids

As the world moves toward DC-native energy sources like solar and wind, the need for advanced conversion systems has skyrocketed.

- Battery Integration: High-capacity DC supplies act as the bridge between renewable generation and battery storage (BESS). They ensure that power is stored and released at the exact voltage levels needed to keep the microgrid stable, whether it’s connected to the main grid or running in “island mode“.

AI Data Centers & Telecommunications

Data centers are undergoing a quiet revolution: they are ditching AC distribution inside the rack in favor of DC-centric architectures.

- Reducing Losses: By distributing power at 48V or 800V DC directly to the server racks, AI facilities can eliminate multiple conversion steps, reducing energy loss by up to 10%. This is critical for data centers supporting AI workloads, where every watt saved translates to better cooling and lower operational costs.

Challenges Facing the Industry

While the future of DC power is bright, the road in 2025 is paved with several complex hurdles. For manufacturers and engineers, navigating these challenges is the difference between a successful deployment and a costly failure.

1. The “Thermal Ceiling”: Managing Heat Density

As power density increases, managing heat becomes exponentially more difficult.

- The Physics Problem: Transistor densities in modern units are so high that “self-heating” can elevate local temperatures by 20–40 K, significantly degrading performance.

- The Solution Gap: While liquid cooling and advanced materials like graphene are entering the market, they are not yet universal. Many systems still struggle with thermal coupling, where heat from one component radiates into another, causing noise and timing errors in sensitive digital controls.

2. Component Scarcity: The WBG Bottleneck

The very materials that make 2025 systems so efficient (GaN and SiC) are also the most difficult to source.

- Supply Chain Fragility: Although the semiconductor market is projected to reach nearly $700 billion in 2025, critical materials like silicon wafers and specialized borates remain concentrated in just a few regions.

- Rising Costs: Demand from the EV and AI sectors has caused price adjustments across the board. In some cases, over 40% of industrial power components have seen price hikes exceeding 30% due to the historic demand for “wide-bandgap” performance. “The price adjustments vary significantly, with basic models generally seeing increases of 10-25%, while more than 24,000 product models (over 40% of the total) experience hikes exceeding 30%”. (Source: AMBLE)

3. The “Certification Maze”: Regulatory Hurdles

Getting a high-capacity power supply approved for global use is more complicated than ever.

- Global Fragmentation: Standards are shifting rapidly. For example, late-2025 mandates like the EU’s Batteries Regulation and updated USB Type-C mandates in South Korea and India mean that a “one-size-fits-all” product is no longer possible.

- Safety & EMI Limits: New high-frequency switching designs are inherently prone to Electromagnetic Interference (EMI). Meeting strict International Special Committee on Radio Interference (CISPR) and International Electrotechnical Commission (IEC) limits while packing 100kW into a 2U rack requires expensive, high-precision filtering that adds both weight and cost to the final product.

Conclusion: Powering the Future with Advanced DC Solutions

High-capacity, wide-range DC power supplies have transitioned from specialized lab tools to the backbone of global electrification. As we move through 2025, these units are providing the versatility, intelligence, and power density required to solve the most pressing challenges in EV development, AI infrastructure, and renewable energy.

With the continued maturation of GaN and SiC semiconductors and the rise of bidirectional (regenerative) architectures, DC power systems are becoming more than just converters: they are becoming high-efficiency energy recycling centers that directly improve the bottom line.

While we’ve focused on DC power in this article, 2025 has also been a landmark year for AC systems. If you’re curious about the latest AC power supply innovations, here is everything you need to know: AC Power Supply Trends: Your 2025 Guide to Power Design.

Frequently Asked Questions (FAQ)

Q1: What is a high-capacity, wide-range DC power supply?

A high-capacity, wide-range DC power supply is a direct-current source that can deliver large amounts of power (often tens of kilowatts or more) while supporting a broad range of voltage and current combinations. Unlike traditional fixed-range supplies, wide-range units automatically adjust output to match load requirements, reducing the need for multiple individual supplies in labs or production environments.

Q2: What does “autoranging” mean in DC power supplies?

“Autoranging” refers to the ability of a programmable DC power supply to maintain full power output over a much wider range of voltages and currents than conventional supplies. This allows one unit to replace several fixed-range units, providing greater flexibility without oversizing the supply.

Q3: Why are wide-bandgap semiconductors (GaN and SiC) important for DC power supplies?

Wide-bandgap materials like Gallium Nitride (GaN) and Silicon Carbide (SiC) enable power supplies to operate at higher voltages, higher switching frequencies, and greater efficiency than traditional silicon devices. This leads to smaller size, reduced heat loss, and improved power density, making them ideal for modern high-capacity applications.

Q4: How do modern DC power supplies support intelligent control?

Advanced DC power systems now incorporate digital control and monitoring features, including remote telemetry, programmable output profiles, and predictive maintenance alerts. These capabilities let engineers adjust power settings remotely and monitor performance in real time, improving reliability and reducing manual intervention.

Q5: What are common applications of high-capacity DC power supplies?

High-capacity, wide-range DC power supplies are widely used in:

- Electric vehicle (EV) battery and drivetrain testing

- Industrial automation and robotics

- Renewable energy systems and microgrids

- AI data centers and telecom equipment testing

These systems provide stable, flexible power for testing, simulation, and operational support in each field.

Q6: What is the benefit of modular and scalable power supply architectures?

Modular DC power supplies let users add or remove power modules to scale capacity as needed. This reduces upfront investment and allows systems to grow with evolving power demands, which is especially useful in labs, EV test facilities, and rapidly changing industrial environments.

Q7: Can autoranging DC power supplies reduce equipment costs?

Yes. Autoranging units let engineers use a single supply to cover multiple voltage/current combinations, reducing the total number of power supplies needed. This flexibility can lower initial costs, floor space requirements, and long-term cooling requirements.

Q8: Why is low ripple and noise important in DC power supplies?

“Ripple and noise” refer to small fluctuations in output voltage. Low ripple/noise is critical in sensitive applications (e.g., precision circuits, RF testing) because it ensures stable and accurate power delivery without interfering with delicate electronics.

Q9: How do high-capacity DC power supplies support renewable energy systems?

In renewable microgrids and battery storage systems, wide-range DC supplies help convert, store, and deliver power efficiently across varying conditions. They act as interfaces between generation sources (like solar panels) and storage loads, ensuring smooth integration and stable operation.

Q10: What makes a DC power supply suitable for data center or AI infrastructure?

DC-centric architectures (like 48 V or higher) reduce conversion losses compared to AC distribution. High-capacity DC supplies can streamline power delivery directly to servers or racks, improving energy efficiency and reducing operational overhead in large facilities